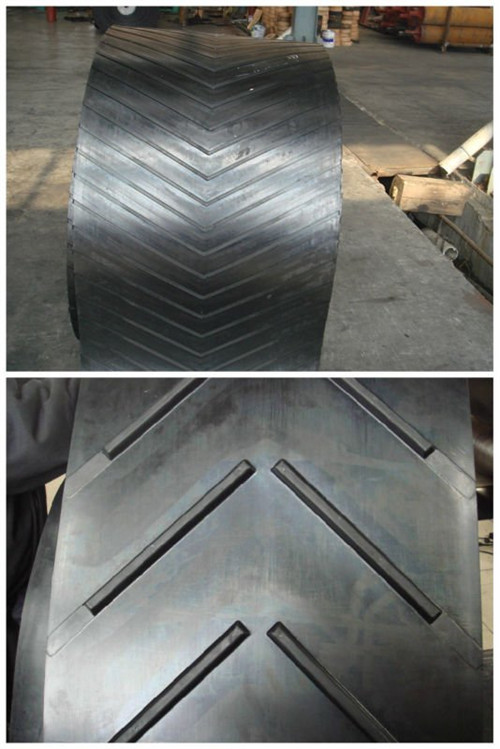

Chevron conveyor belt

Chevron conveyor belt are used primarily when the angle of incline becomes too steep for a smooth conventional conveyor belt. The belt is fitted with integrally moulded cleats which prevent the material from sliding backwards as would be the case with a smooth surface belt. Different cleat designs allow the carrying of many types of material, from bulk solids to unit loads.

Application: There are open type and closed type, suitable for bulk or bagged materials such as powder and granule with incline less than 45 C.

Type: C5,C8,C15 etc. More type are avaible soon .

Standard : The Standard will be exactly follow GB/T 7984-2001、DIN 22102

The Adhesion and Elongation of the Belt

|

Adhesion strength

|

Elongation

|

|

Belt carcass

|

Between plles N/mm

|

Between rubber and carcass

N/mm

|

Longtudinal elongation break

|

Longtuainal elongation rate at reference load

|

|

Rubber thickness

|

Rubber thickness

|

|

|

|

EP canvas

|

≥4.50

|

≥3.15

|

≥3.50

|

10

|

1.5

|

|

Belt Type

|

Fabric Type

|

(N/mm)Single Fabric Strength(N/mm)

|

Single Fabric Thickness(mm)

|

Rubber Top Bottom Rubber

|

Width Range(mm)

|

Length(m)Roll

|

|

Cotton Conveyor Belt

|

CC--56 TC--70

|

56 70

|

1.10 1.0

|

2mm-8mm

|

400mm-1000mm

|

20-300

|

|

Nylon Belt

|

NN100

|

100

|

0.7

|

|

NN150

|

150

|

0.75

|

|

NN200

|

200

|

0.9

|

|

NN250

|

250

|

1.15

|

|

NN300

|

300

|

1.25

|

|

NN400

|

400

|

1.5

|

|

EPBelt

|

EP100

|

100

|

0.75

|

|

EP150

|

150

|

0.85

|

|

EP200

|

200

|

1

|

|

EP250

|

250

|

1.2

|

|

EP300

|

300

|

1.35

|

|

EP350

|

350

|

1.5

|

|

EP400

|

400

|

1.65

|